Dendrochronological core drill: Handling-instructions

The core drill (for technical data see under dendro drill >) is the result of a long series of tests and has been specially developed by us for use in dendrochronology. It is made in Germany and consists of HSS steel (high-speed steel). In addition, the individual components of the drill are hardened differently for the respective application. The drill has a shank for a 13 mm drill chuck. Drills suitable for the purpose of dendrochronology include the Metabo B E 622 S- R+L or comparable types. With a maximum of 600 rpm and 620 W, this machine delivers the ideal number of revolutions and develops a comparatively high power. Today, cordless drills can also be used without restriction. We can recommend the following machines: Makita DHP481 or Bosch Professional GSR 18V-55. With a fully charged 5.0 Ah battery, up to 10 samples can be obtained in oak wood; in softwood at least 15. Nevertheless, it is always advisable to carry one or two rechargeable batteries.

It is for these technical data that this machine can be often found in carpenters’ workshops. Because of its high torsional force the drill must be used only with the additional handhold (within the scope of supply).

Please take care that your drill still has a functioning drive arbor. You will get the best results with key-type drill chucks, which can easily be re-stressed. Older drive arbors often have worn-out chuck jaws which are no longer able to hold the core drill sufficiently. Result: The borer slips through the drive arbor. As an additional effect due to worn-out chuck jaws, imbalances may occur, which negatively affect the concentricity of the core drill. Therefore the exchange of the drive arbor every once in a while should be as natural as the re-sharpening of the core drill itself.

Notice: The tool can only be used with the assistance of a fence (special tool, within the scope of supply)!

Drilling on the object under investigation should only be done with moderate pressure. Pay attention to the ejection of the borings. The borings should be ejected constantly and uniformly. If the ejection should be interrupted while drilling, the core drill must partly be pulled out of the borehole and afterwards carefully lead in again. Doing this will eject compressed borings from the borehole. Especially in case of wood with high moisture-contents the borings often agglutinate.

The thread of the borer must never be treated with oil. In case of sluggishness it has to be treated with a wire brush first. Afterwards it can be maintained with graphite or a copper paste (for example OKS 240, commercially available) to regain the ease of motion. Do not adjust the thread by using wrenches; adjustment by hand is totally sufficient. If both parts of the tool have to be separated from each other, work can be done with two open-end wrenches of 17 mm.

a sharp drill bit!

If the sample should be broken and it/ or parts of it should be stuck within the drill, we recommend to separate the core-drill from its thread using the 19 mm open end wrenches. Afterwards the sample may be pushed out carefully by using the 10mm round-steel stick (within the scope of supply). The core should be pushed out in direction of the thread. If pushed in direction of the drill bit, the sample might become even more stuck or may be damaged because of an offset about 15 mm underneath the drill bit.

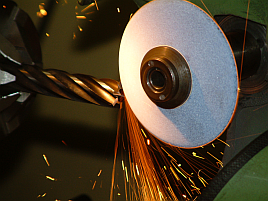

Too much heat generation does harm to the core drill and in the worst case deteriorates the hardening of the steel. To avoid this, work should be interrupted if too much heat generation occurs so that the tool may cool down. Under normal conditions overheating should never occur, but might happen if the drill bits sharpening has perished and propulsion has to be gained by applying more and more pressure to the tool. Normally moderate pressure is sufficient for the propulsion of the core drill. If much force is needed for propulsion this indicates that the drill should be re-sharpened soon.

If the drill bits become tarnished in a blueish colour, this indicates the need for re-sharpening too. Referring to the experiences made so far, a hundred of drillings may be done before a re-sharpening is needed.

We strongly recommend against attempts to re-sharpen the core drill autonomously. At a normal level of deterioration we are able to re-sharpen the borer in our own workshop.

If the sharpening should be highly deteriorated, it has to be treated by a specialised company. For a successful sharpening it is vital to keep the correct angles of the drill bit. Solely by this means a proper function of the core drill can be guaranteed.

Our tools are provided with a special coating which enhances the ejection of the borings and reduces congestions in the drill hole.

Therefore it is possible to work with constant propulsion. Broken core-samples may be reduced too, although cannot be ruled out completely. Because of that, drilling should be done only by applying moderate force to the drill.

The wear-resistance of the coating is limited and cannot be hold up in perpetuity. Nevertheless, the type of coating is a good compromise between wear-resistance and the ejection of borings. In the case of the coating we decided for optimized ejection of borings. Referring to our experience, no coating had ever to be refreshed so far, although hundreds of drillings were made. However, coating suffers from a dull drill because of the great heatwhich is generated when operating a

dull drill. That is why we -again- strongly recommend a timely re-sharpening. If the coating should be deteriorated due to utilization it may be applied again. For costs please refer to our pricelist.

Referring to recent experience the core drill is not suitable for green wood!